Our Products

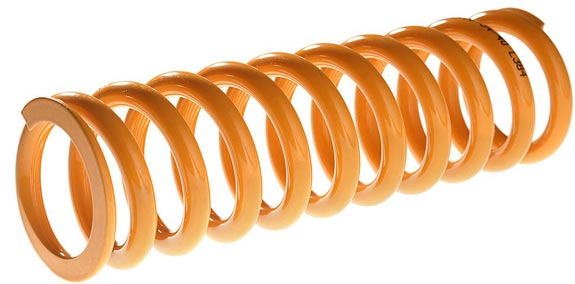

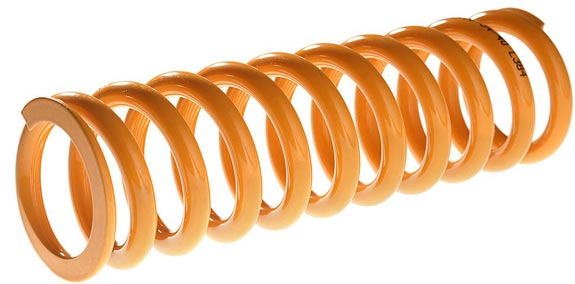

Compression Spring

Compression Spring

Our compression springs offers uniform tensile strength and have anti-corrosion properties. We also offer compression spring as per client specifications.

Compression Spring

We are known to manufacturer, supplier and trader of all types of Compression Springs till 0.2 to 60 mm diameter. Our compression springs offers uniform tensile strength and have anti-corrosion properties. We also offer compression spring as per client specifications. The offered range is precisely designed at our highly advanced manufacturing unit following industry defined guidelines. The offered range can also be availed from us at the industry leading prices.

Features:

• Sturdiness

• Anti-corrosive

• Durability

Specifications:

• Size: 0.2 to 60 mm diameter

• Compression springs with variable or constant helix angles, single and multiple conical shapes, with closed or open ends

• Compression springs with variable or constant helix angles, single and multiple conical shapes, with closed or open ends

Tension Spring

Tension Spring

Tension springs are designed to give a specific pull force when extended to a specific length. The Features are Good quality and Excellent finish.

Tension Spring

Specification Range:

• 0.1mm to 70mm (As per Requirement)

• Backed by a rich industrial experience, we have come up with a world class assortment of Tension Spring.

• Features:

• Durable

• Good quality

• Excellent finish

Rubber Bush Spring

Rubber Bush Spring

A rubber bushing is a type of vibration isolator. It provides an interface between two parts damping the energy transmitted through the bushing.

Rubber Bush Spring

• A bushing or rubber bushing is a type of vibration isolator.

• It provides an interface between two parts, damping the energy transmitted through the bushing.

• A common application is in vehicle suspension systems, where a bushing made of rubber (or, more often, synthetic rubber or polyurethane) separates the faces of two metal objects while allowing a certain amount of movement.

Moulding Spring

Moulding Spring

Structure consists of sheet metal body with a spring wound placed on a shaft that holds a tensioned system known for its shielding ability.

Moulding Spring

Specifications:

• Material: Stainless Steel 302, 304, 316/Inconel Material

• As per Grade: 1, 2, 3, 4 upto customers requirement

• Sizes: Ranging from 0.2 mm to 30 mm

• Music Wire

Stone Crusher Spring

Stone Crusher Spring

We specialize in offering a wide range of Stone Crusher Springs to our clients.

Our range is widely used in various industries.

Stone Crusher Spring

Specification:

• Output Torque: 4~2320Nm

• Output Speed: 14~186.7rpm

• Rated Power: 0.04~22kW

• Input Speed: 1400rpm(4pole)

Torsion Spring

Torsion Spring

A Torsion Springs works by torsion or in other words by twisting.It exerts force in a circular arc and the arms rotate about the central axis.

Torsion Spring

• A Torsion Springs works by torsion or in other words by twisting.

• It exerts force in a circular arc and the arms rotate about the central axis.

• The amount of force (torque) varies directly with the amount of twisting.

• The stress is in bending and not in torsion.

• It is necessary to specify torque with deflection or with the arms at a definite position.

• These can be used in a variety of devices like pendulums, automobile.

Spiral Spring

Spiral Spring

A spiral spring usually has a hook or screw hole on the end that extends away from the spiral.A spiral spring is a unique type of flat spring.

Spiral Spring

• A spiral spring is a unique type of flat spring that can be made out of various metal materials and

is bent into loops that form a spiral.

• A spiral spring usually has a hook or screw hole on the end that extends away from the spiral.

• This point is used to attach the spring to whatever component it will be functioning with.

• The center of the spiral will also usually have a hooked shape that can be fixed to a component that holds

it in place when the spring is activated.

• Available in various sizes, dimensions and thicknesses, these springs can be

customized as per the needs and requirements of our esteemed clients.

• The entire qualitative array can be availed from us at industry leading prices.

Feature

• Low cost, effective teaching.

• Self-contained.

• Wall mounted.

• Measurement of oscillation frequency.

• Demonstration of Hooke's law for torsional spring.

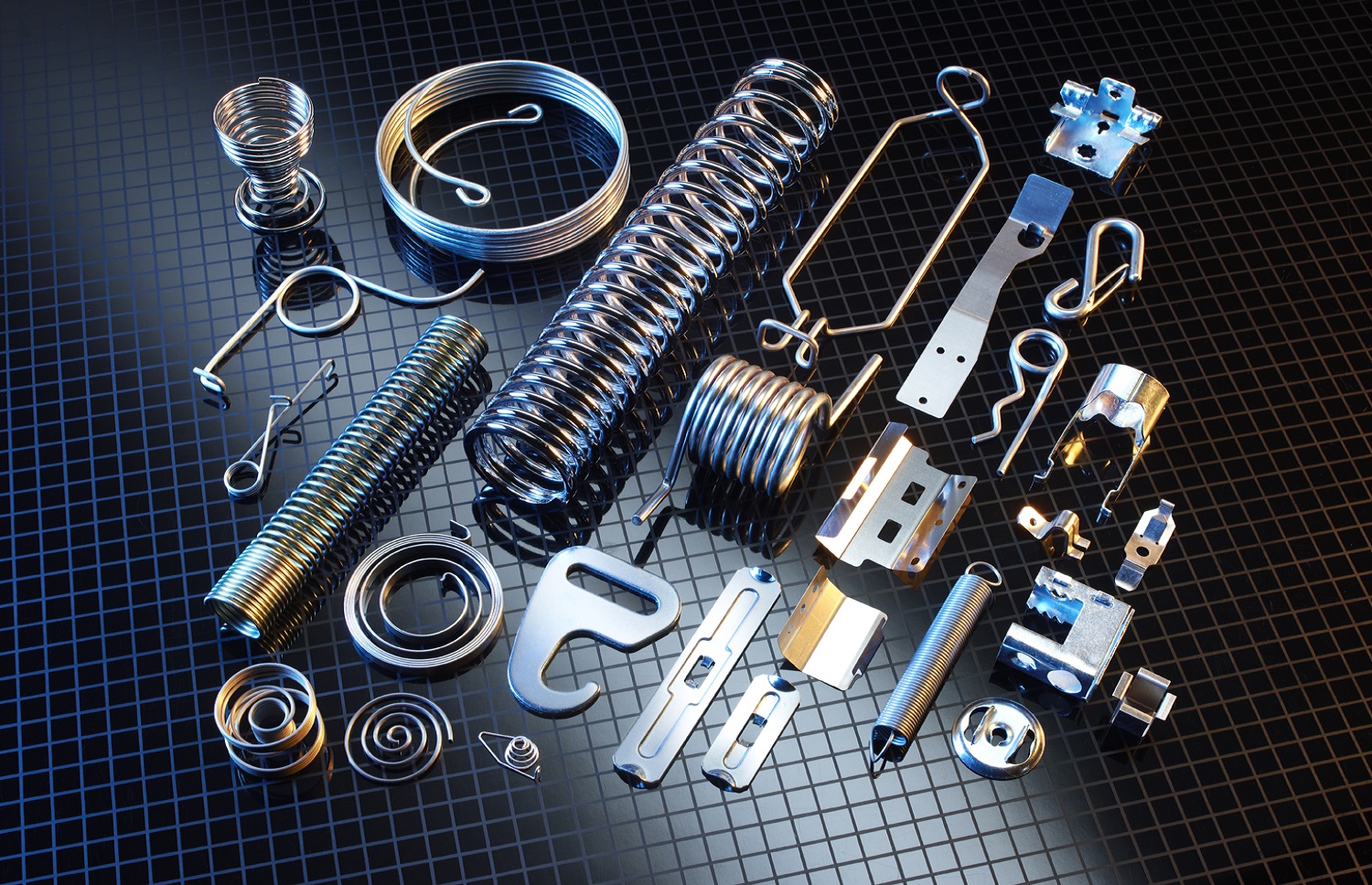

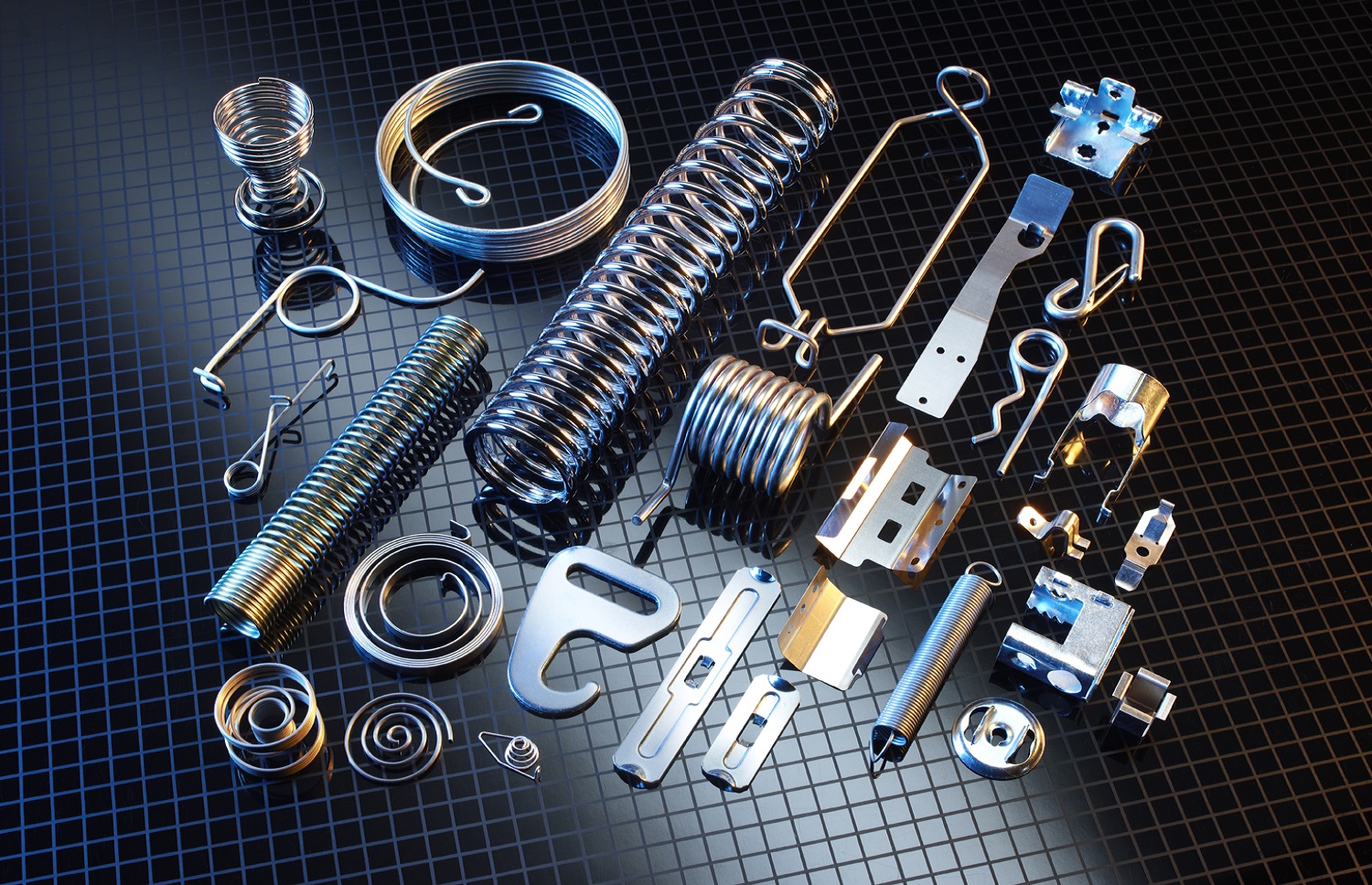

Wire Form Spring

Wire Form Spring

In order to cater the ever changing demands we are offering our respected clients a wide range of Stainless Steel Wire Form Spring.

Wire Form Spring

-

• Wire forms spring have a wide range of available designs, with the only limitations being in the

imagination of the designer and the skill of the machine setter.

• Through continued investment in the latest CNC coiling and wire forming machines we are able to produce a range of wire form shapes.

Features

• Cost-effective

• Longer service life

• Dimensionally accurate

• Optimum operation

• High performance

Specifications

• Material: Stainless Steel 302, 304, 316/Inconel Material

• As per Grade: 1, 2, 3, 4 upto customers requirement

• Sizes: Ranging from 0.2 mm to 30 mm

• Music Wire

Hot Coil Spring

Hot Coil Spring

Hot Coil Springs are generally used in elevated temperatures high load applications in a corrosive environment.

Hot Coil Spring

• Hot Coil Springs are generally used in elevated temperatures high load applications in a corrosive environment.

• The transportation industry agriculture implement manufacturers and construction equipments manufacturers are some of the largest users of the hot coiled springs.

• The slabs are heated in a natural gas fired furnace before processing it through a hot rolling mill. This process reduces the thickness.

Specifications

• Thickness (mm): 1.60 to 20.0

• Width (mm) : 2000 max

• Length : As per customer requirement

• Coil Weight: 30 MT max

• Grade : O,D,DD,EDD,IF,FE 410

Zigzag Spring

Zigzag Spring

Zig Zag Spring is perfect for seat and furniture restoration.This is flexible to meet the various requirements and has exceptional strength.

Zigzag Spring

• Zig Zag Spring is perfect for seat and furniture restoration. This spring is flexible enough to meet the various requirements and has exceptional strength.

• Zig Zag Springs (also known as No-sag or Serpentine springs are used a lot in modern furniture .

• A minimum of 5 springs should be used under each seating area i.e. chair = 5 springs, 2 seater sofa =10 springs. However the more zig zag springs used the firmer the seat.

• When the zig zag springs are fitted across the seat they should be almost flat with just a slight dome upwards and all the zig zag springs should then be tied into place with laid cord, three rows across a normal size seat.

• The zig zag springs are then covered with hessian and a padding, we recommend Typar Felt as it is very strong and easy to use.

• The seat can then be covered with calico and/ or your top cover. The zig zag springs are stocked in standard sizes but can be easily cut with a hacksaw if you need to adjust the size.

Clamp Spring

Clamp Spring

A clamp is a fastening device to secure objects tightly together to prevent movement or separation through the application of inward pressure.

Clamp Spring

• A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure.

• In the United Kingdom and Australia, the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash cramp but a wheel clamp or a surgical clamp.

Features:

• Sturdiness

• Fine finish

Specifications

• Free length: 75 mm Reference

• 330mm (13 inch) Spring Kit

Hook Spring

Hook Spring

hooks are manufactured as per the set industry standards by making use of high-grade raw material and advanced technology.

Hook Spring

-

• We hold expertise in manufacturing, supplying and exporting a superior quality range of Spring Hook

• These hooks are manufactured as per the set industry standards by making use of high-grade raw material and advanced technology.

• Hook-like surface structures, observed in some plant species, play an important role in the process of plant growth and seed dispersal.

• In this study, we developed an elastic model and further used it to investigate the mechanical behaviour of fruit hooks in four plant species, previously measured in an experimental study.

Features

• Accurate dimensions

• Durability

• Corrosion resistance

Specifications

• Spring hook for fastening tools to the slide hanger:

• Quick, easy replacement

Strip Spring

Strip Spring

These strips are stocked in different width, finish and different hardness range between 40 50 HRC.

Strip Spring

• We hold vast expertise in offering a high quality range of Strip Springs to our domestic clients.

• To assure high durability and optimum performance of these springs, the entire range is fabricated using finest quality steel.

• Assuring easy maintenance, light weight and corrosion resistance, these components find extensive application in various automobile and engineering industries.

Heavy Duty Coil Spring

Heavy Duty Coil Spring

Heavy duty spring used in mechanisms that require a great amount of force to be exerted on the spring.

Heavy Duty Coil Spring

• Heavy duty compression springs are used in mechanisms that require a great amount of force to be exerted on the spring. You may find heavy duty compression springs in heavy construction machines, agricultural equipment, industrial equipment and oil field equipment. These springs may be found in stock through a stock compression spring catalog but could also be custom-made if you aren't able to find what you need in stock.

Specifications:

• Material : Carbon Steel; Spring Steel; Stainless steel

• Wire Dia. : 0.01mm – 12.00 mm

• Surface treatment : Zinc, Nickel, Silver, Golden, Tin, Powder Coating, Phosphate

• Applications : Automotive, medical device, electronics, Toys etc

Densar spring

Densar spring

Tension springs are designed to give a specific pull force when extended to a specific length.

Densar spring

• Compression springs are the most recognizable spring and are intended to oppose compaction in the direction of the axis.

• The spring is extended at rest; shortened and stored with energy when a load is applied, and is one most efficient energy storage devices available.

• Traditionally, they are wound and uniform in pitch and diameter, but these traits vary considerably today.

Dimensions, load and materials determine the deflection of a compression spring.

• The spring is fully extended when at rest.

• Upon compression, the spring will express stored torsional energy in a pushing force.

• The shape-restoring force is proportional to the deflected distance of the spring.

Thicker-coil, thinner-diameter springs require heavier loads to begin compression.

• Spring material also determines the linear elasticity of the spring, with more rigid materials providing stiffer resistance and a higher return force.

Agriculture spring

Agriculture spring

Agricultural Springs, which we make available are precision engineered and designed with full perfection. Exporter and Supplier of Agricultural Springs.

Agriculture spring

• Agricultural Springs, which we make available are precision engineered and designed with full perfection.

• We are a well-known Manufacturer, Exporter and Supplier of Agricultural Springs from New Delhi, India.

Features:

• Optimum durability

• Rugged design

• Supreme finish

Specifications:

• Usage: Agricultural

• Size: Customized

Coper coil spring

Coper coil spring

Tension springs are designed to give a specific pull force when extended to a specific length.

Coper coil springg

• Compression springs are the most recognizable spring and are intended to oppose compaction in the direction of the axis.

• The spring is extended at rest; shortened and stored with energy when a load is applied, and is one most efficient energy storage devices available.

• Traditionally, they are wound and uniform in pitch and diameter, but these traits vary considerably today.

Dimensions, load and materials determine the deflection of a compression spring.

• The spring is fully extended when at rest.

• Upon compression, the spring will express stored torsional energy in a pushing force.

• The shape-restoring force is proportional to the deflected distance of the spring.

Thicker-coil, thinner-diameter springs require heavier loads to begin compression.

• Spring material also determines the linear elasticity of the spring, with more rigid materials providing stiffer resistance and a higher return force.

Automobile spring

Automobile spring

These springs are processed employing optimum quality raw material to maintain the international quality.

Automobile spring

• These springs are processed employing optimum quality raw material to maintain the international quality standards. • Being a quality-centric firm, we insure the quality of these products by rigorously testing on varied quality factors.

• The spring is extended at rest; shortened and stored with energy when a load is applied, and is one most efficient energy storage devices available.

Features:

• Abrasion resistance

• Rust resistance

• Precise design

Specification :

• Size- 0.20mm to 2.50 mm•

• Following machines are used : Coiling Machine, Torosion Machine & Wire Forming Machine, CNC wire forming machine

• Material : Spring Steel Wire, Stainless Steel Wire, Galvanised Iron Wire, HB Wire, Phosphor Bronze Wires etc.

• Uses : Industries such as Electronics, Toys, Home Appliances, Automobiles etc

Boiler Tube spring

Boiler Tube spring

The offered products are manufactured in compliance with international quality standards using premium quality raw material and the latest technology.

Boiler Tube spring

• This product is manufactured with great precision using an optimum quality material in adherence to international quality standards.

• The spring is extended at rest; shortened and stored with energy when a load is applied, and is one most efficient energy storage devices available.

Specifications:-

• Material: - SS

• Size: - Customized

• Brand: - Alika Steel Traders

Features:

• Reliable performance

• Sturdiness

• Dimensional accuracy

Powder Coting lock

Powder Coting lock

The powders are sprayed electrostatically onto components and then fused into a uniform and durable coating.

Powder Coting lock

• Powder coatings are powder materials that consist of pigmented thermoplastic particles.

• The powders are sprayed electrostatically onto components and then fused into a uniform and durable coating.

• Powder coatings are applied to cleaned, sandblasted surfaces that are free of dirt, oil, and paint.

• To prevent corrosion, degreasing may be required. An operator then uses a special gun to apply powder coatings made of resin and pigment.

Pipe Coil Spring

Pipe Coil Spring

coil pipes are utilized in a variety of applications including bicycle brake cables and control cables within flexible boroscopes or animatronics.

Pipe Coil Spring

• Minimum Order Quantity 1 Kilogram

• Size 1/2 inch, 3/4 inch, 1 inch, 2 inch, 3 inch

• Unit Pipe Length 3 meter, 6 meter, 9 meter, 18 meter, Customized

Features

• Anealed, Pickled, Polished, Cold Drawn